31 Jan CBC and NTN: A smooth venture

The marketing motto adopted by Japanese-founded bearing manufacturer NTN, with its history of more than 100 years, is to ‘make the world ‘NAMERAKA’, with ‘NAMERAKA’ meaning ‘SMOOTH’ in Japanese. It’s an apt tagline as NTN is renowned for its production of anti-friction bearings, which are made to be smoother than the surface of a mirror.

This phrasing could also be used to describe the unique relationship between NTN and CBC (Inenco) Australia. The two companies have been working together in Australia since the 1970s when the Japanese manufacturer began to grow its business abroad and shook hands with CBC founders to exclusively distribute NTN product in the country. The relationship forged back then paved the way to the long term–a 50/50 a joint venture company in Australia.

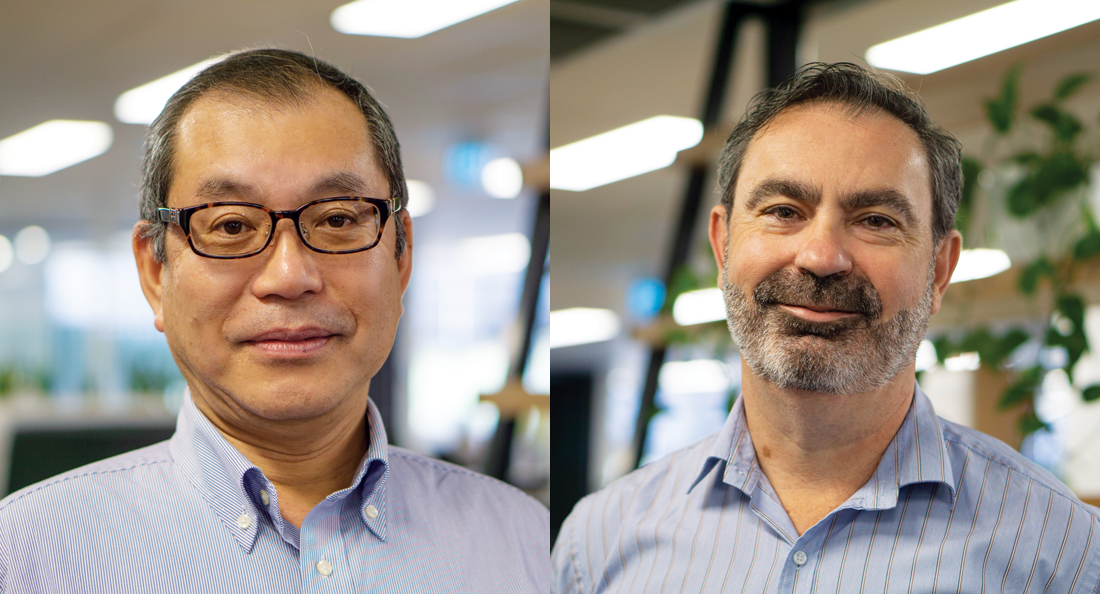

“It was a natural progression from the good relations that already existed between the CBC founders and Japanese management of NTN. Together, we are responsible for the entire territory, including the sales and marketing, business development, and engineering support of the NTN product in Australia,” explains Jerry Maki, who is a director of NTN-CBC Australia.

This arrangement bodes well for customers across all market segments in Australia, including the food industry where NTN is recognised as a leader for its special environmental bearings range. These bearings are designed specifically to withstand high humidity, along with the impact of cleaning agents and regular washdowns, abrasive contaminants, and the need for restrictive lubrication use, which are common to food processing facilities.

In terms of NTN’s reputation and ability to manufacture bearings that meet the high standards of the Australia food industry, product manager for NTN-CBC Australia, Fabio Rebecchi, draws an analogy between the NTN business and Japanese food.

“In Japan, the standards of the food industry are very high – and this is seen across all levels of dining, even the food that is served on trains. And that same expectation is assumed in business. It’s a clear reflection of how NTN does business and the products that they manufacture. NTN focuses highly on quality in whole process,” he says. “And this comes back down to why we have been so successful in promoting NTN product in Australia, because this standard permeates through everything.”

Importantly, NTN-CBC Australia is uniquely positioned in the NTN global family because of Jerry Maki’s very presence. Known affectionately by his moniker Jerry – which he good-humouredly suggests is to “avoid the embarrassment of Australian friends mispronouncing my name” – Maki has held various posts of NTN Sales and is an acting director of the NTN-CBC joint venture business. This affords a number of benefits to NTN-CBC Australian customers, one of which is the ability to provide direct feedback from customers to the manufacturer.

“Bearings are highly engineered products. So being that bridge to Japan where we can provide feedback about specific customer requirements is a big benefit. We have total access to the manufacturing division,” explains Jerry. “It’s all about uptime of machinery with the customer, and us providing superior products. And we can provide that through a number of different avenues, whether that is in material enhancements or design enhancements in Japan.”

Moreover, Jerry brings a wealth of experience to the table. He has worked with NTN since 1981 and been placed in eight different countries by the company. And while he agrees that there are “superficial” differences between the countries he has worked in, there is a lot of commonality, especially when it comes to bearing-related applications and issues seen across the globe. He now has the rare ability to consolidate that experience into tangible benefits for customers of NTN-CBC Australia.

“This venture is not just a joining of two worlds but various worlds – it is global. It is one of the key advantages of me being here,” Jerry says.

Opening up that channel of communications is an enormous asset to NTN-CBC, echoes Rebecchi.

“Jerry Maki is not only an asset for NTN international or NTN-CBC but most importantly to our customer base because he can tap into all levels and aspects of the NTN global network,” Rebecchi says. “And our close relationship with customers allows us to give a direct contact to the plant and therefore shorten that lead time process from conception, design and delivery. This is very important in Australia which is very diverse, even within the food sector itself, and it’s a large country that can be difficult to get around. We rely on our network of branches and our sales engineers in the field to really assist in making that process better for the customer.”

NTN-CBC Director, Mr Jerry (Takao) Maki

After graduating from university, Mr Takao Maki went to work for NTN back in 1981. His career has not been a typical one, having spent the majority of his professional life outside of Japan.

“Many Japanese people will stay inside the country when they are in a sales role, but I’ve had the opportunity to go abroad and learn from people around the world. Actually, I’ve been out of Japan in various roles a total of eight times,” says Maki, who is known as ‘Jerry’ by his non-Japanese speaking friends across the globe.

Jerry has spent five years in the United States, eight years in Canada, four years in the United Kingdom, and a few years in France, Thailand and China. In between all of those, he continued working in Japan for NTN too and in roles that have encompassed business development and management, marketing, sales, communications and public relations. While he’s only been in Australia since August 2019, he enjoys the friendly nature of his Australian colleagues and has a love for rugby.

“What I’ve learned from my experience living abroad is that we have more in common than we have in differences,” Jerry says. “While this is a new experience for me, to work in a joint venture in with CBC (INENCO) in Australia, I feel that we can consolidate many global requirements together to make production easier. To use rugby talk, we wear the same jersey in the scrum to get the ‘TRY’ together.”