11 Apr Gates® Innovates Food & Beverage Power Transmission

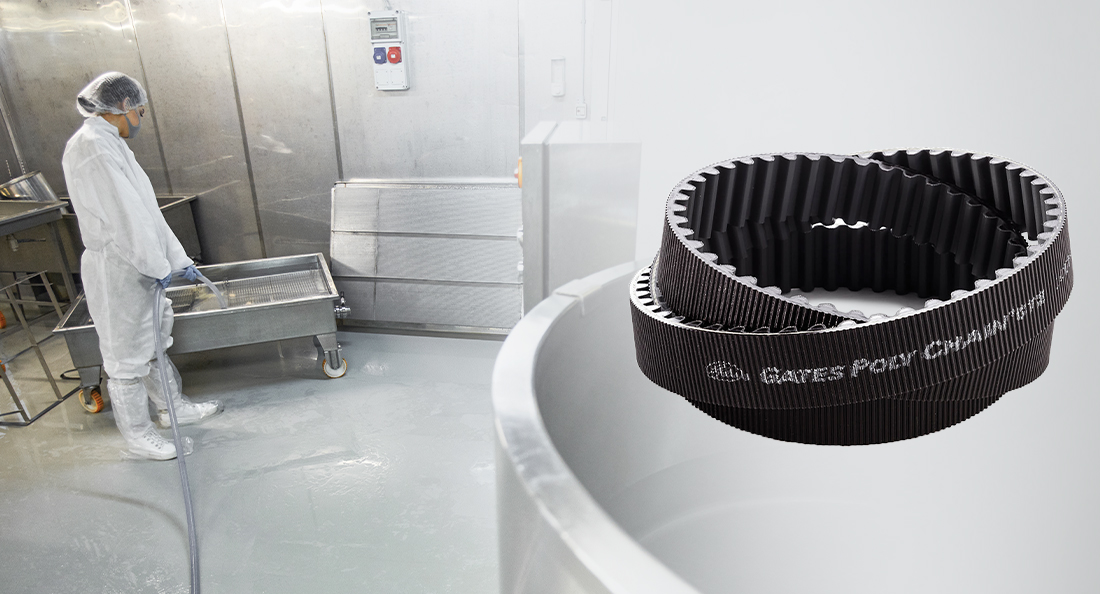

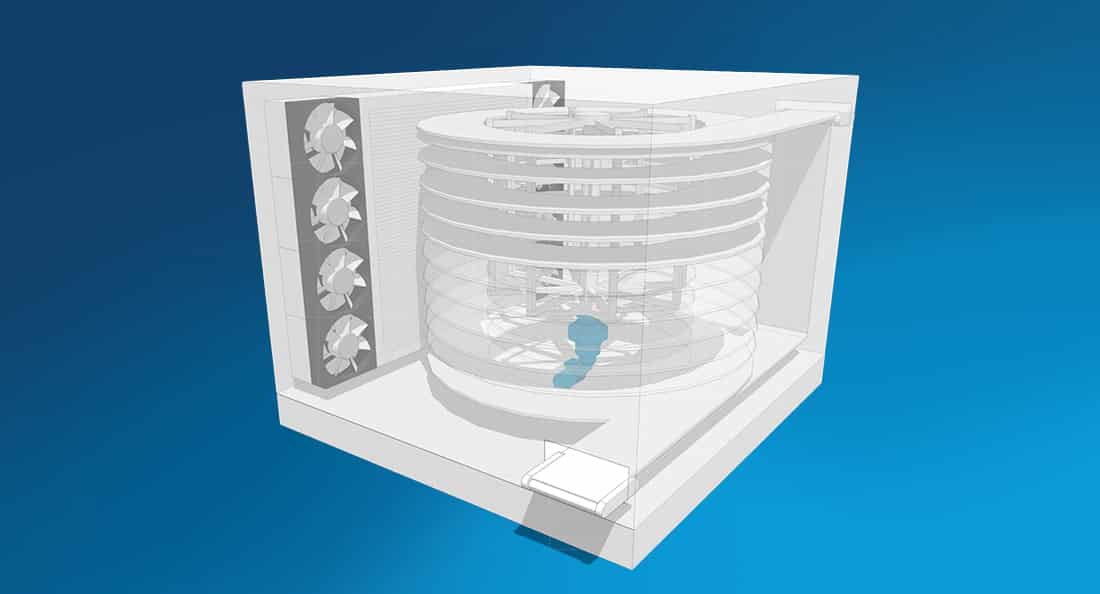

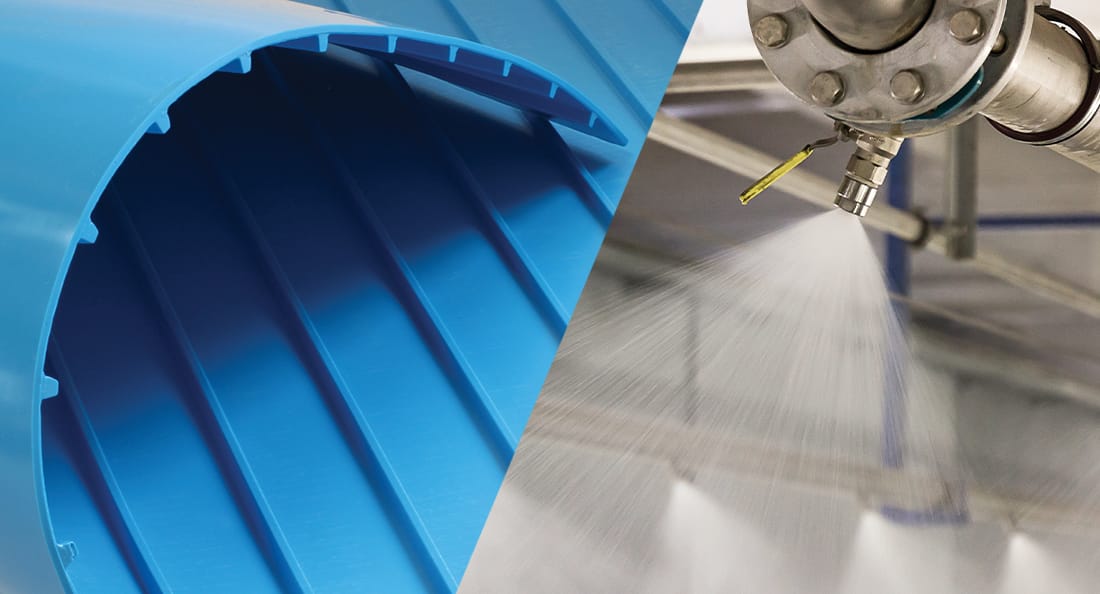

As the food and beverage industry places increasing emphasis on safety, efficiency, and hygiene in power transmission, Gates®, a renowned manufacturer of drive belt solutions and the original inventor of the V-belt, is leading the way with a ground-breaking innovation. The Poly Chain® GT™ Carbon™ synchronous...