20 Apr Gates POSICLEAN belts are saving water in food processing plants

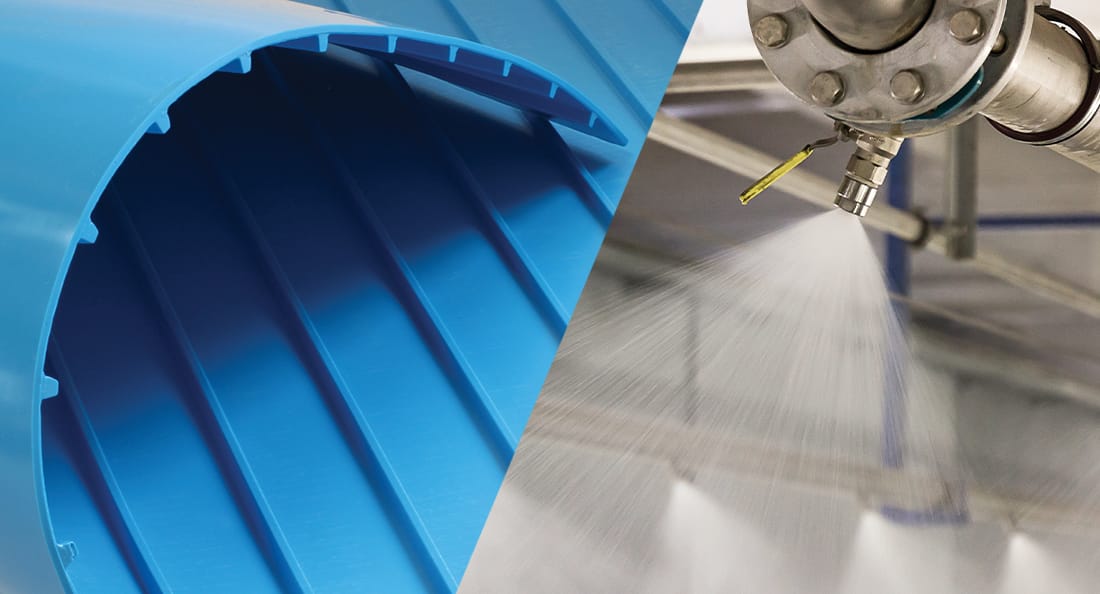

Water usage is a major financial and environmental cost in food processing sectors, due to the rigorous cleaning procedures required to maintain hygiene standards. Gates, a Diamond supply partner with Motion Australia, is now offering the POSICLEAN™ thermoplastic polyurethane belt line as a long-wearing alternative, incorporating sealed tension and full belt width drive teeth and ‘clean in place’ (CIP) capabilities.

“This exciting new product is now available to Australia’s poultry, pork and seafood industries,” says Leon Stefanec, Victorian State Sales Manager at Motion Australia. “Typically, it would replace plastic modular belting, commonly seen in these areas. This has the potential to provide huge water consumption benefits, translating to important environmental and dollar cost savings.”

Case studies by Gates have demonstrated an almost 50 per cent reduction in water usage where the Gates POSICLEAN has been implemented, saving 172,000 galleons per year on a single meat processing plant.

To read the full article, please click here.