11 Apr Reliable Conveyor Chains for Food & Beverage by Rexnord

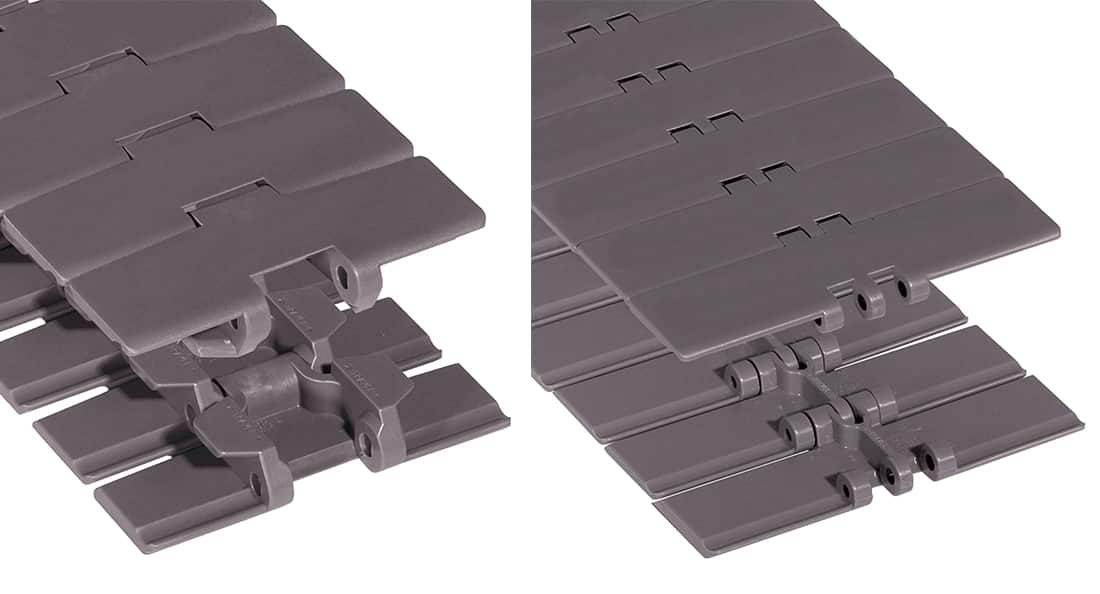

Rexnord, a trusted name in conveyor chain solutions, offers a best-in-class portfolio of MatTop® and TableTop® Conveyor Chains, along with Rexnord® Conveyor Components. With a team of experienced application engineers, Rexnord provides reliable and versatile products that cater to the unique needs of the food and...