20 Dec Pressing out problems

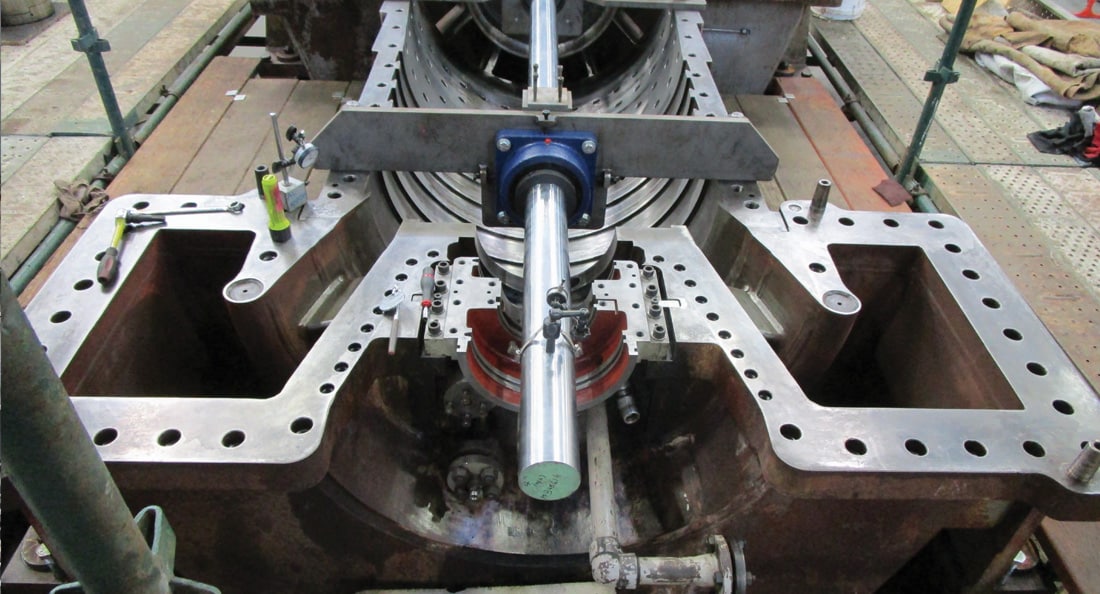

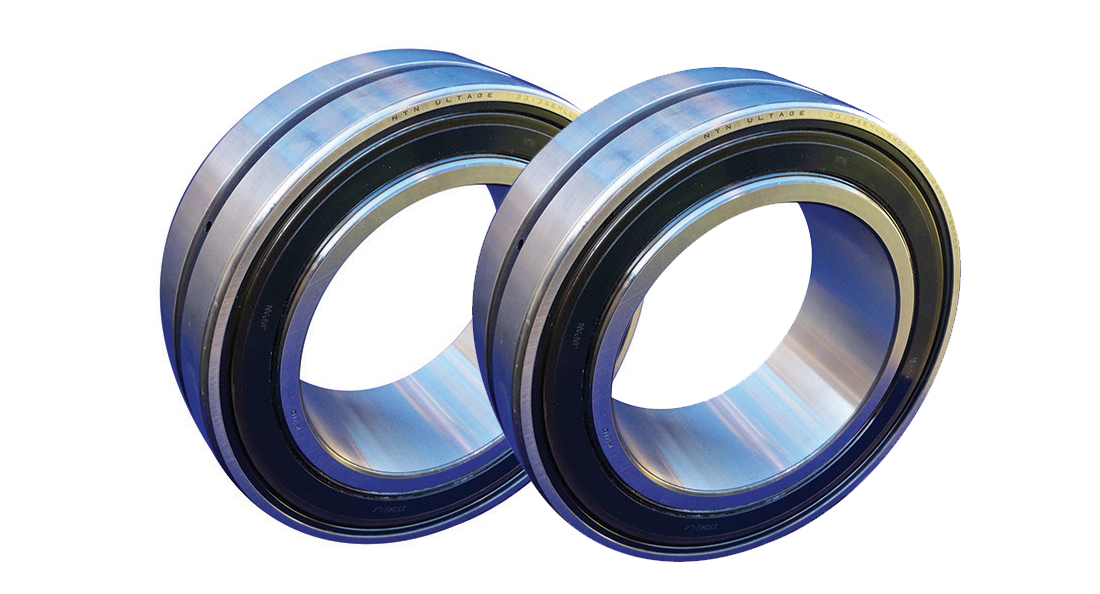

After treated paper pulp is pressed into long sheets, it is fed through large steam-heated dryer cylinders, removing any excess water and bonding the fibres into a more stable structure. According to Nitin Verma, Industrial Business Development Manager at NSK Australia, the key challenge with...