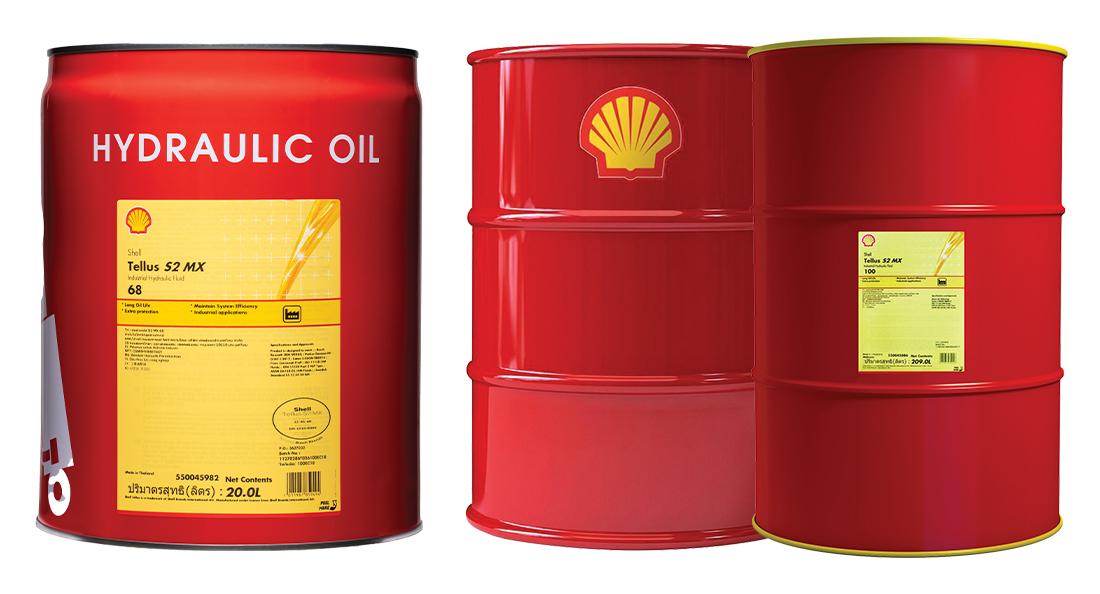

16 May Lube it or lose it with Shell hydraulic oils

In the waste management and recycling industry, conveyors are a vital component in the process of sorting and recycling waste. To ensure that these machines operate efficiently and safely, proper maintenance is crucial. Conveyors are used to transport various materials such as plastic, paper, and metal...