15 Jul Ahead of the curve with ongoing flood recovery projects

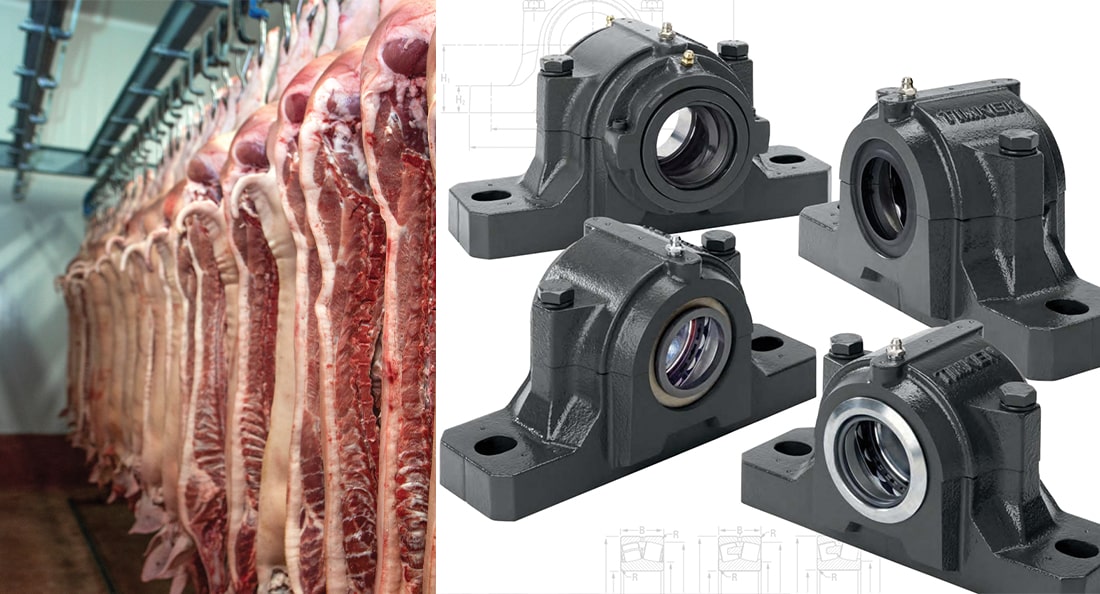

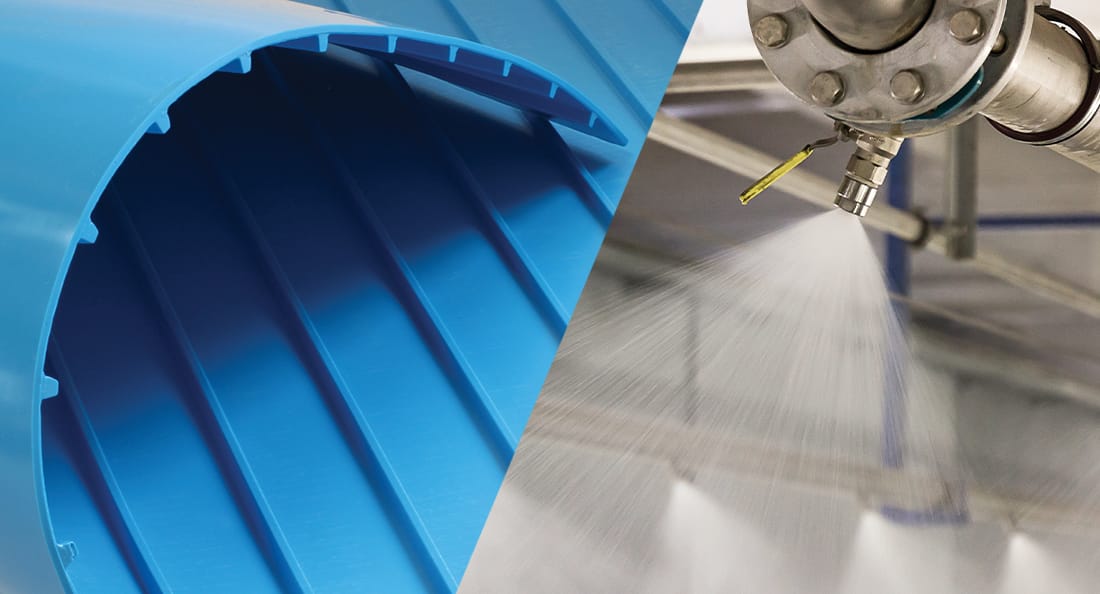

Following a record-breaking flood season in the first half of 2022, Queensland and New South Wales have been left with extensive damage to industrial machinery and infrastructure. Motion Australia is working to engage with affected communities, ensuring that supply of vital parts and servicing continues. “We...