22 Feb A Shell Lubricants guide to drive line lubrication

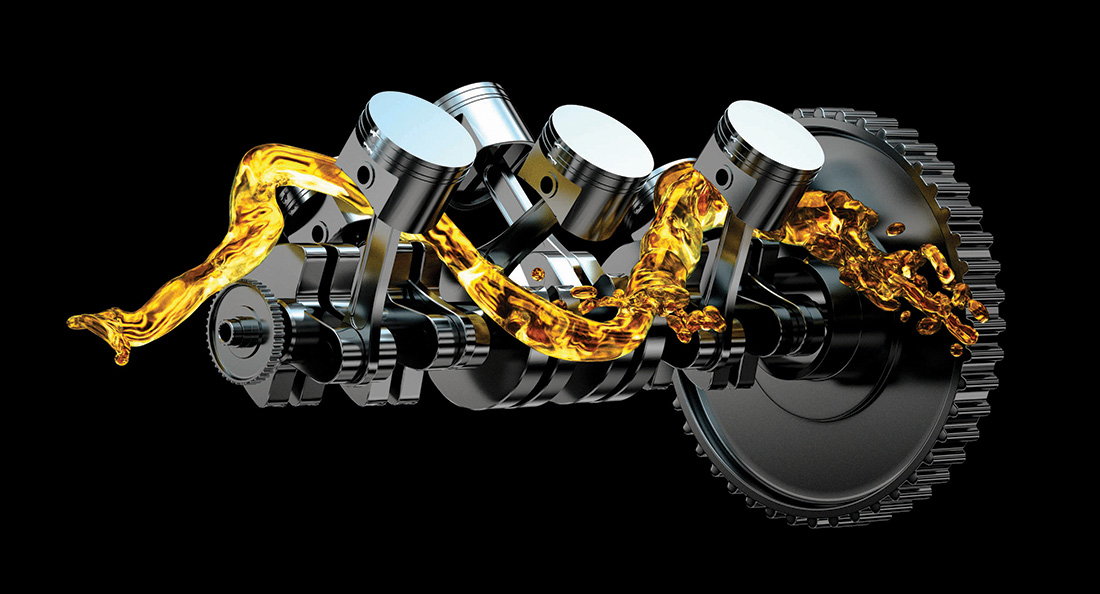

According to Shell’s industry research, lubricants account for only around 1-2% of total maintenance costs. Yet if chosen correctly, many operators do not realise that choosing the right lubricant product for a piece of equipment can save up to 30% on total operating costs. Further research...