14 Mar Tips for ensuring safety during machine maintenance

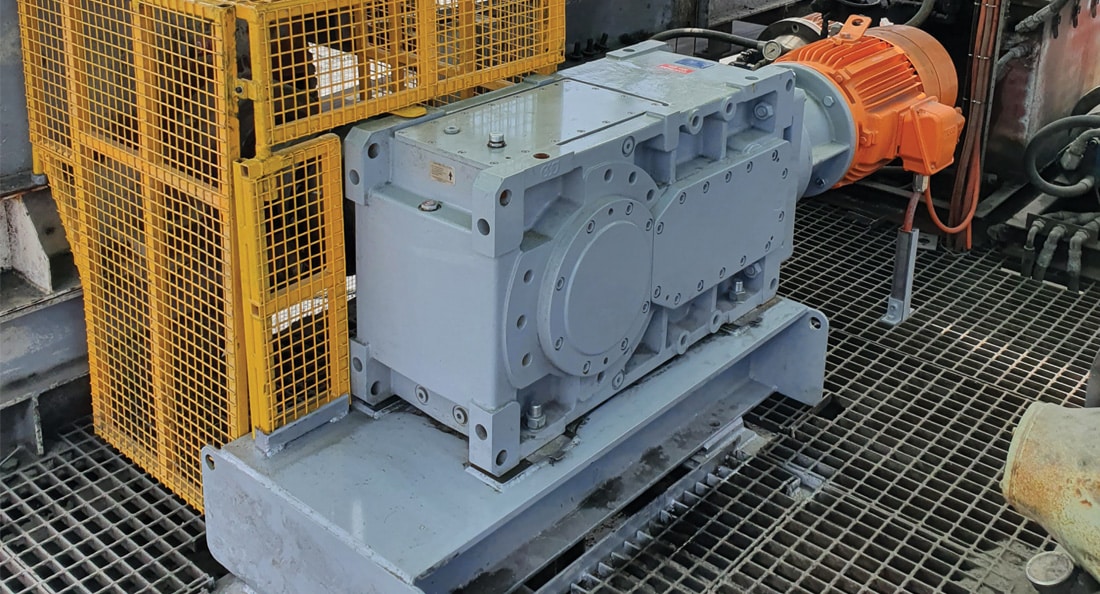

In any industry, the efficient operation of machines is vital for achieving high-quality production. However, one crucial aspect that is often neglected is the proper maintenance of oil. CRAM engineering expert, Josh Cornish, sheds light on the significance of machine maintenance and its associated risks. He...