09 May Preventive maintenance puts the ‘shhh’ in belt drive systems

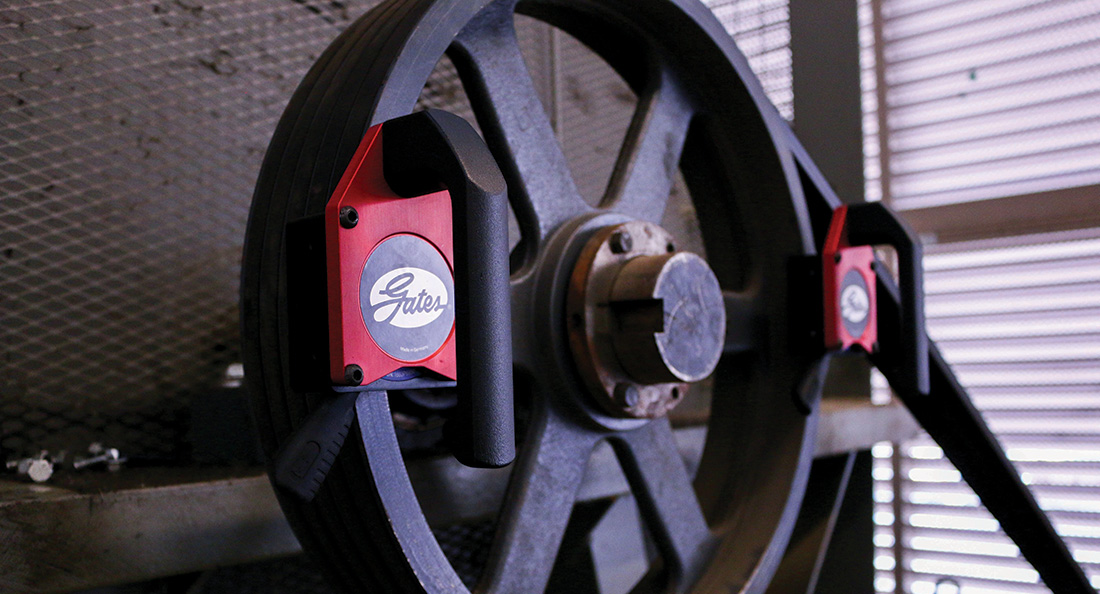

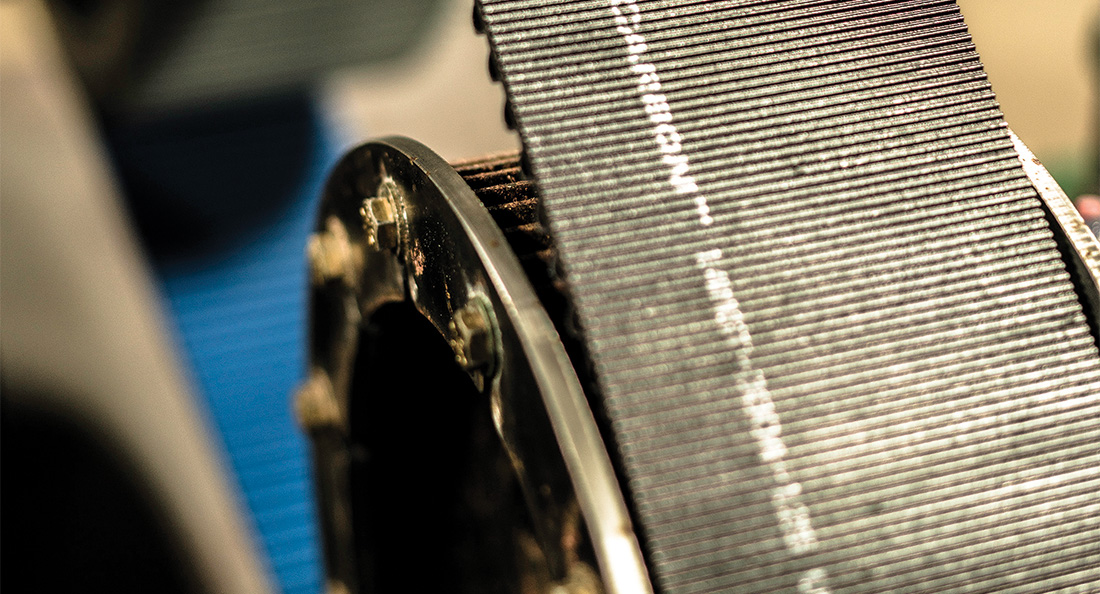

A chirping sound, however pleasant when you are taking a stroll through the park, is an unwanted noise when it emanates from a revved up engine at your plant – as it’s often indicative of a misaligned pulley. Belt drive systems are used extensively in water and...