20 Jun Simplify mining operations with Schaeffler

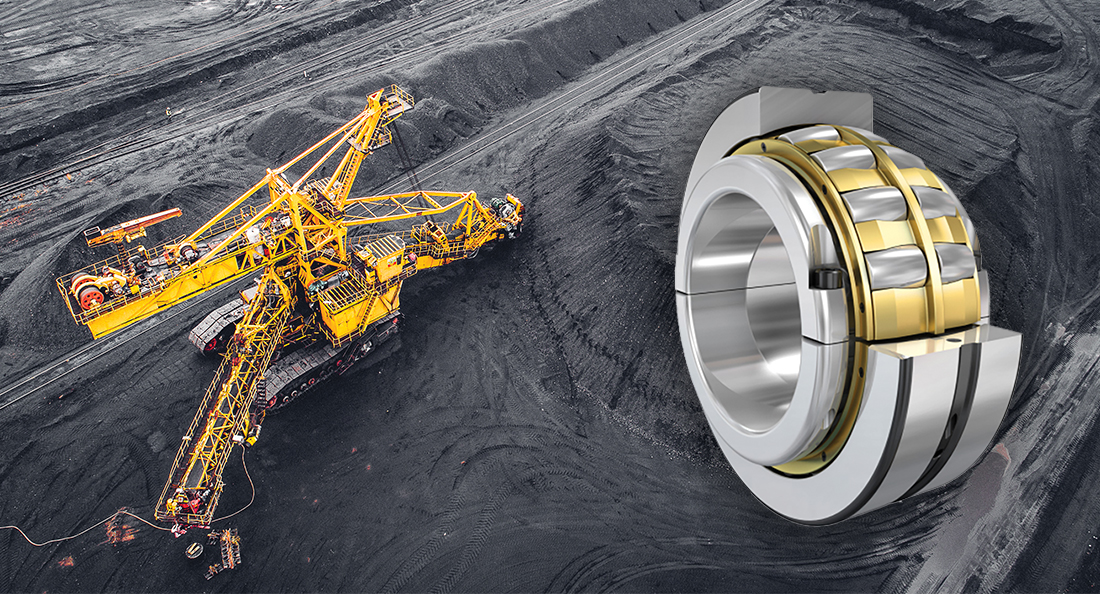

When it comes to bearing replacement in mining operations, professionals seek a solution that enables swift and efficient replacement, minimising the need for extensive disassembly. Schaeffler's split bearings offer a reliable and convenient solution for in situ replacement, allowing mining professionals to swiftly resume their...