16 May Rough copper mining sites opt for super strength drive belts

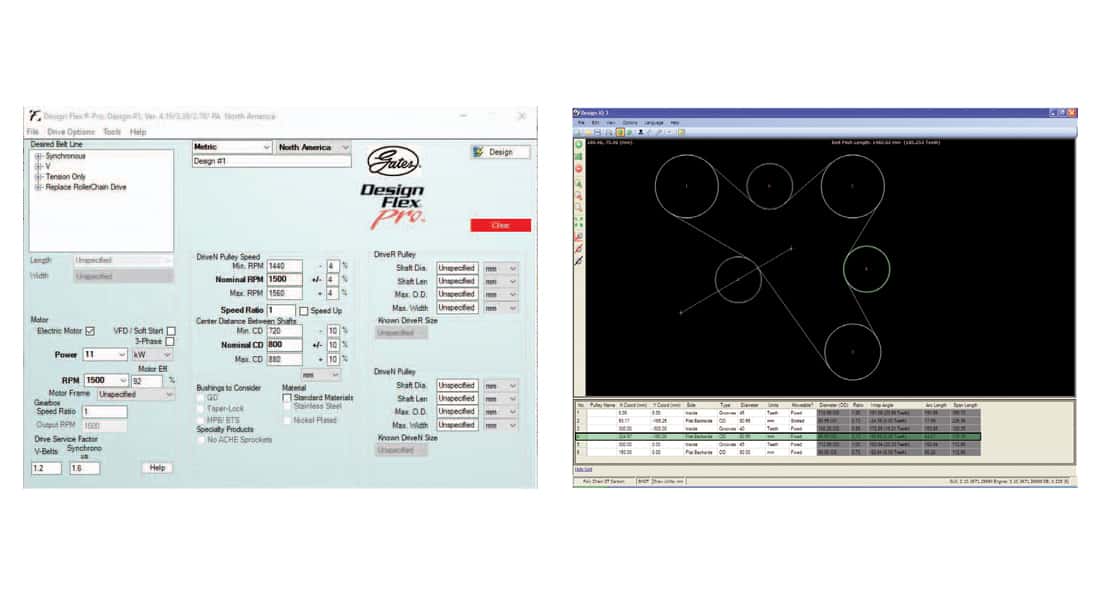

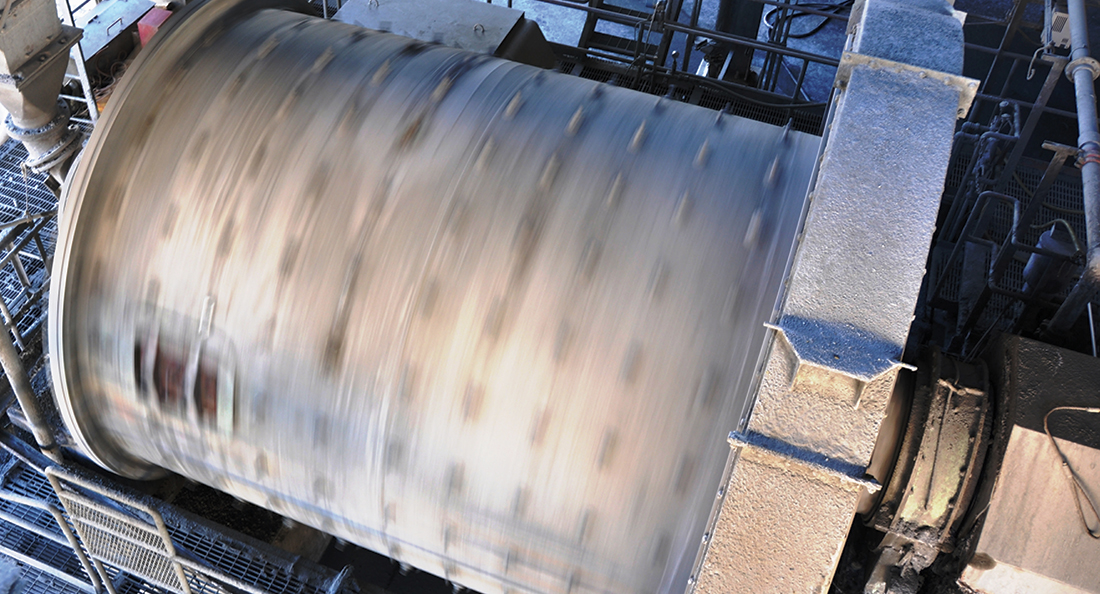

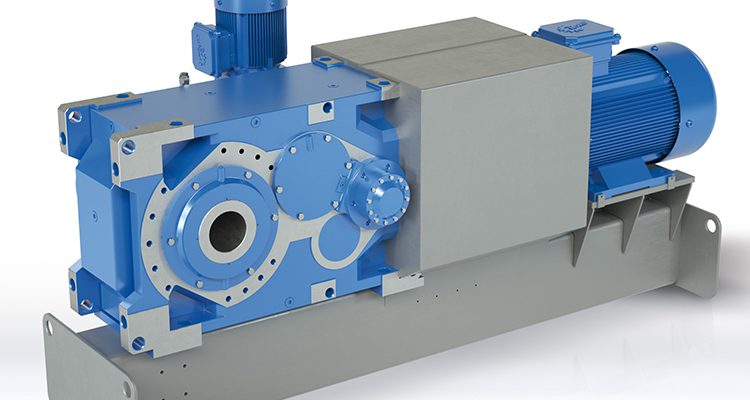

The collaborative relationship between component manufacturer and supplier is crucial when it comes to offering full-spectrum service to customers. This is exemplified by CBC’s recent implementation of the Gates Super HC cross-section V-belts to a copper mine in Townsville. “When Gates and CBC are both involved...