Coal Mines Tag

14 Feb Innovative coupling solutions for mines and quarries

One of CBC Australia’s key partners for shaft coupling products is Timken®, which provides the Timken Quick-Flex® shaft couplings to operate in harsh environments, especially within industries such as mines and quarries while requiring minimal maintenance.27 Nov Gates Predator v-belts

Gates’ high-quality Predator v-belts by have unrivalled high-load carrying capabilities, making them extremely effective for uses in mining operations. The v-belts are covered for extreme abrasion and wear resistance, so they are protected from oil, dirt, heat, fatigue and shock loads. Not only are the belts themselves...

24 Oct V-belt health in coal mining: Wambo case study

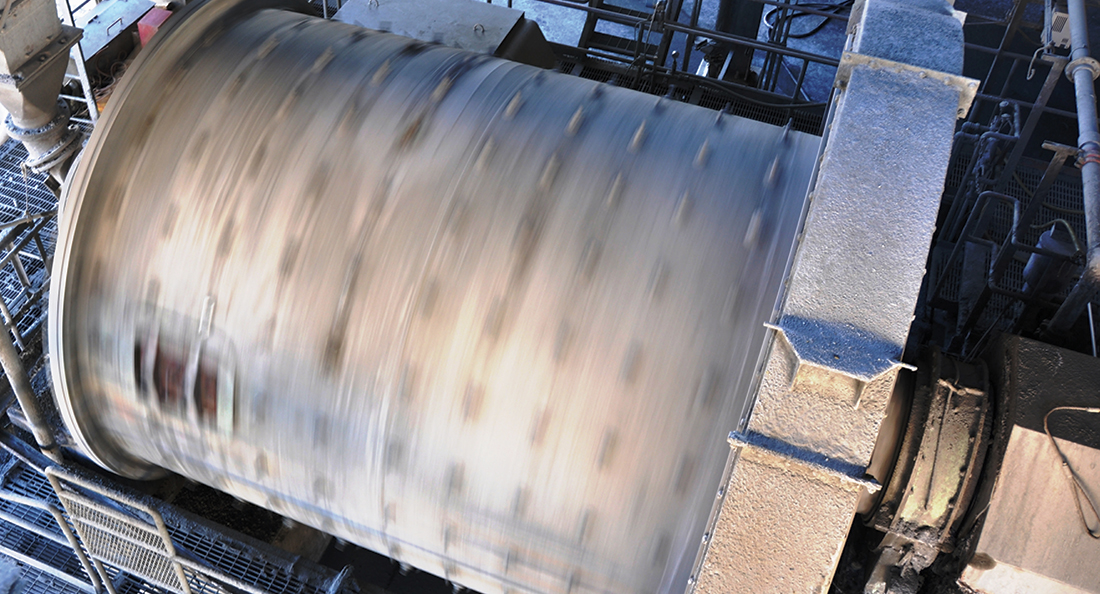

Coal mines are notoriously high-stress environments for machines to operate in due to the contamination of parts. Regular maintenance regimes are therefore essential to keep rotating equipment in working order in the larger coal mining operations. Wambo is an open-cut coal mine in the Hunter Valley...

19 Sep Withstanding harsh environments

As mining companies look to cut costs and reduce downtime associated with machinery, Gates offers the market its Predator V belts. Australian Mining writes. Mining operations are often exposed to the harshest of climates and naturally, this has an effect on machinery and equipment that must withstand the rigours...

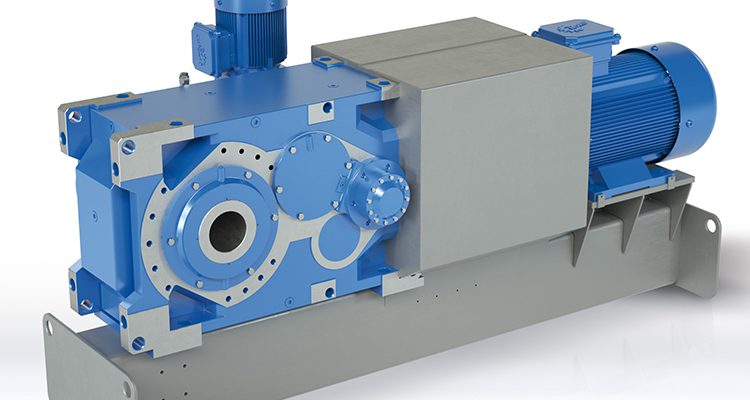

07 Aug Nord Drivesystems partners with Inenco to deliver industrial gear units

To help keep conveyors and feeders running smoothly across a variety of industries, Nord Drivesystems has implemented a line of modular industrial gear units (IGU). Nord’s IGUs have been designed with a range of individual components that can change to match exact requirements for a specific...