23 Jun Sealing the deal with NTN triple-sealed bearings

It’s not uncommon for machinery in building material manufacturing to be exposed to large amounts of dust or water splashing. Be it in cement production plants, brick kilns or steel mills, heavy air-borne dust and high humidity can greatly impact the bearings’ performance.

That is where Tony Tormey, Product Manager for Industrial Bearings at CBC, suggests switching from standard range bearings to NTN’s triple-sealed bearings to help extend the bearings’ life.

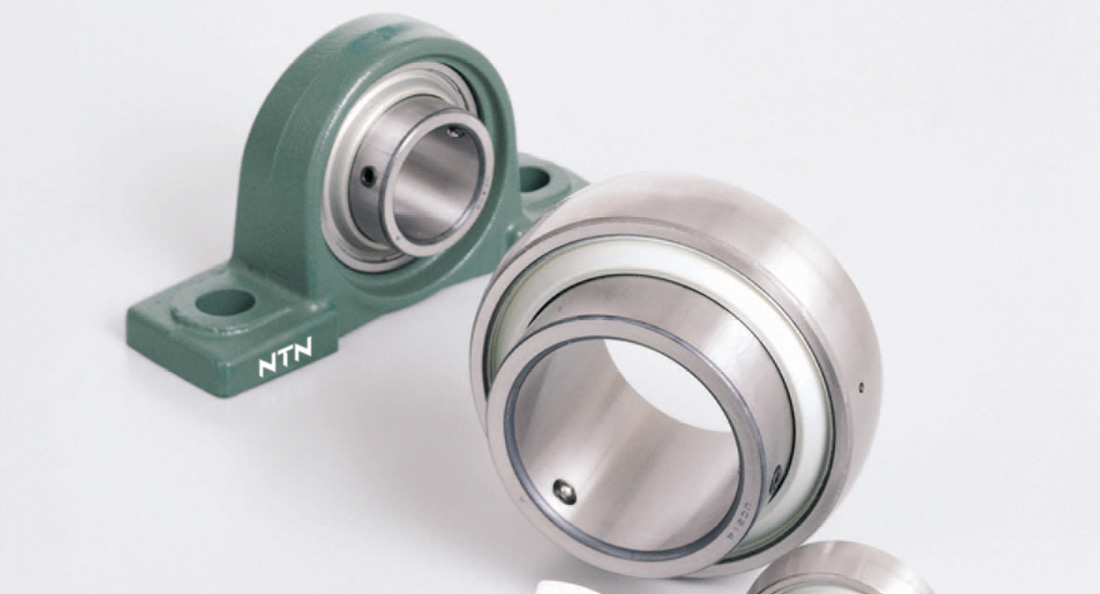

“Triple-sealed bearings, as the name suggests, are wide inner-ring bearings encased within three sealing lips for maximum dustproofing and waterproofing. This enhanced protection gives the bearings longer service life and extended maintenance intervals,” he explains.

CBC has been the primary distributor of products by Japanese bearing manufacturer NTN for the past 47 years. The NTN-CBC joint venture company has been fulfilling the Australian market’s requirements for quality bearings over the years.

NTN-CBC Product Manager for Bearings Fabio Rebecchi says original equipment manufacturers (OEMs), as well as maintenance, repair and operations (MRO) businesses, can all benefit from the extended bearing life that the triple-sealed NTN bearings offer.

“Our tests have shown that by changing from standard-type bearing to a triple-sealed bearing, you can get in excess of five times more life out of the bearings,” he says. “Testing the bearings against muddy water, we have seen similar performance, where the triple-sealed bearings last around five to seven times longer than standard bearings.”

Fabio says the NTN triple-sealed bearing units are designed to be easily interchangeable with conventional covered bearing units.

“The triple-sealed bearing is not only ready to use as a re-lubricable bearing, but it also readily replaces the conventional bearing units of NTN and other manufacturers. The bearing conforms to the JIS (Japanese Industrial Standard) for UC-type bearings and therefore serves as a ready replacement for existing bearing units,” he explains.

Further, Fabio says the units can be customised to incorporate different pre-lubricated grease specifications, depending on the application they serve.

“The standard pre-lubrication for bearings in this series is Li-mineral grease. But the NTN engineering team can provide optional bearings lubricated with solid grease or food-grade grease, or for bearings made of stainless steel,” he explains.

And while having three seals on the bearing slightly limits the bearing’s maximum speed capacity, Fabio says this rarely poses an issue with the majority of applications.

“Most bearings are never required to run at their maximum speed capacity. For example, many bearings are designed with capacities in the range of 5,000 rounds per minute (rpm) but in practice hardly ever run over a few hundred rpms. So, the lower speed capacity almost never poses an issue.”

Fabio says the close partnership between CBC and NTN provides customers with the advantage of being directly connected to the manufacturer.

“Because we have a direct line of communication to the factory, should a customer need any product enhancements, we can engineer those product enhancements. We can also work with the factory to improve production lead times to be able to meet our customer at a price point which they require to utilise and build their machinery,” he says.

The full factory backing also helps the NTN-CBC joint venture to ensure flawless stock availability, according to Fabio.

“We place orders directly to the factory so we have visibility of our orders and we know at what stage of the manufacturing process they are at,” he says. “We therefore can relay this exact information to the CBC sales network and schedule production to meet our customers’ request. We also have a very good stocking program within Australia.”

Being able to service customers with a range of engineering services and sales requirements is what Tony says the CBC team prides itself on.

“From stores and plants audits to advising on best practices for bearing fitment or storage for all rotating equipment, the CBC team of experienced personnel is happy to help our customers with all of their rotating needs,” he concludes.